Specialty coffee roasting

Learn how we roast specialty coffee directly in our cafeteria

The coffee roaster that is in our premises is not a decorative element! Every week, we roast specialty coffee from different origins depending on the demand of our customers. We are going to tell you more, so you know the process!

1. Reception of specialty coffee in green

We bring to our location coffee beans qualified as specialty by the SCA (Specialty Coffee Association). Which we store ensuring the appropriate temperature and humidity conditions for subsequent roasting. Once we have the green bean in optimal conditions we can proceed with the roasting process itself.

2. Preheating the toaster

We heat the toaster, specifically the drum where the coffee will circulate through electrical resistances. Thanks to the touch panel we establish a target temperature at which we will introduce the coffee (this will depend on the bean, but let's say between 180 and 220 degrees). At the same time, we preheat our smoke burner, which will be responsible for eliminating the smoke generated during the specialty coffee roasting process.

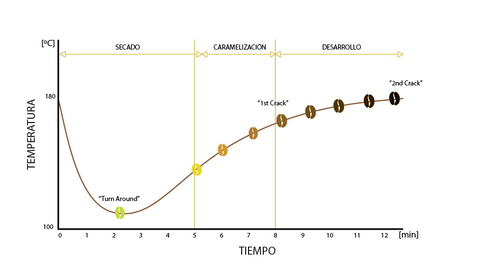

3. Coffee drying

We open the upper gate that will drop the green bean into the toaster drum, where it will begin to rotate giving way to the first stage of roasting: drying. During this phase, moisture will be removed from the coffee. This will give way to the first pronunciation of the temperature curve of the coffee profile. The appearance of the coffee bean hardly changes in this phase. Maintains its shape and color. We will notice how the temperature drops considerably until the point called "Turn Around", from which the temperature of the drum equals that of the coffee bean and will begin to increase.

4. Caramelization

In this phase, the Maillard reaction will begin, this is a chemical reaction between sugars and amino acids that will give the characteristic flavor and color of toasted foods. This will give a yellow color to the coffee bean. The grain will begin to expand and detach from its shell, which will be collected by aspiration and stored in a specific deposit. Finally we will observe how the coffee acquires brown tones thanks to the caramelized sugars.

5. "First Crack"

The accumulation of CO2 and water vapor inside the coffee bean will increase its pressure until it produces a small explosion that we can hear perfectly (similar to that of a popcorn). The grain can double in size. From this point on, the coffee could be used to make coffee, but it will depend on the type of roasting we want to do, whether we decide to remove it or let it continue to the next phases.

6. Development

In this phase the roaster will decide when to take out the coffee depending on the flavor he wants to obtain. The longer we roast the grain after the "First Crack" the less acidic and sweet it will be since the sugars and acids will caramelize. If we wait too long, the grain will suffer a second explosion, which means that the structure begins to destroy. The grain will become darker and oils will begin to appear, while at the same time it will obtain a more bitter flavor. Basically, the grain has been burned.

7. Refrigeration

Once the grain is removed from the drum, through a second gate, it will fall into the refrigerator. This is a tank in which the grain will rotate, lowering its temperature for about 5 minutes so that it can be bagged later.

8. Bagging / storage

Once the entire roasting process is finished, it is crucial to preserve the grain in special containers. These are what isolate moisture and oxygen, but allow the escape of the carbon dioxide that the coffee contains after roasting. We must store it for at least 1 week before we can serve it or sell it, to ensure that the grain is ready to consume.

This is how we roast our coffee

Do you want to try it?

Visit our Store